Piping

Pipeline Systems (onshore & offshore)

We help clients across the oil and gas sector to innovate and adapt to challenging environments

Whatever your project, you will benefit from our four decades of experience in oil and gas. We’ll work with you to find the best way to strengthen your project, minimise your risk and ensure your success, whether that involves oil, natural gas.

We closely cooperate with our clients by understanding their specific challenges and needs. As long-term partners, we are often reappointed by our clients for the safe and timely implementation of fast-track projects. Our full range of services spans from concept to commissioning, including advisory and feasibility studies.

ScientiCal Energy offers tools for reducing supplier risk and for renewing the procurement operating model. Through the use of an efficient purchasing platform the purchasing of indirect goods and services becomes extremely easy for the rest of the organization.

ScientiCal Energy procurement division is responsible for planning demand, allocating technical and operational expertise and approving suppliers recommended by the relevant procurement entity. The procurement function is authorised to sign binding agreements with suppliers on ScientiCal Energy’s behalf.

The procurement function is responsible for proactive coordination, planning and execution of procurements within:

- Drilling mobile units and LWI Drilling services fixed platforms

- Drilling rigs onshore

- Geodata processing and acquisition

- R&D studies

- Surface equipment

- Well services

- Drilling services

Instrumentation

Increasing device complexity and technology convergence are driving test systems to become more flexible, while cost pressures are demanding longer system lifetimes. A software-defined, modular architecture is the only way to accomplish these objectives. Modular instrumentation uses shared components, high-speed buses, and open, user-defined software to meet the needs of automated test equipment (ATE) today and in the future.

ScientiCal Energy is able to provide high quality and cost saving souring for equipment, spare parts through our international network in Europe, US and Asia within

Process Piping including:

• Pipe

• Fiting

• Flange

• Valves- (All types & class)

• Bolt & Nu

• Gasket

• Filter & Strainer

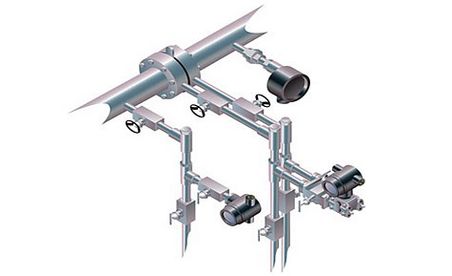

Integration

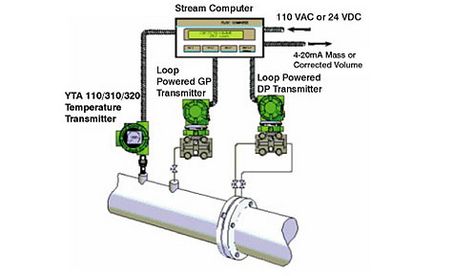

All instruments in a modular instrumentation system share a power supply, chassis, and controller, while stand-alone instruments duplicate these components for each instrument, adding cost and size and decreasing reliability

Transmitters including : Pressure Transmitters , Level Transmitters , temp. transmitter

Actuators including : MOV's , ESDV , Control Valve ,etc.

Gauge : All type & Range

Tube & Fitting

Indicators

Level Switch's

Flow matters & transmitter

Valve

Type:

Ball valves

Gate valves

Globe valves

Check valves

Plug valves

Choke valves

Control valve

Butterfly valves

Needle valve

Safety valves

Hydraulic Actuators

Pneumatic Actuators

Emergency shutdown valve

Line break valve

Materials:

Carbon steel

Low temperature carbon steel

Cast iron

Stainless steel

Forged stainless steel

Alloy steel

Low alloys

Bronze

Aluminum

Inconel

Monel

Nickel

Titanium

Classes:

150 lbs up to 4500 lbs

2000 Ibs up to 15000 Ibs for API 6A valves

Sizes:

1/4” up to 72”

Standards:

API 6A

API 602

API 6D

API 600

NACE MR 0175/ISO 15156

ASME

ANSI

ASTM

ISO

Fitting / But weld Fitting

TYPE

90° Elbows

45° Elbows

Tees

CON. Reducer

ECC. Reducer

Caps

Standards

EN 10253

DIN 2605, 2615, 2616, 2609

NF A 49-281, A 49-289

ASME B 16.9

ASME / ASTM A234, A420, A403, A815

MSS SP 75, SP 43

CSA Z245.11

Mechanic

Mechanical Rotating Equipment Engineering

ScientiCal Energy is Lead Mechanical and Rotating Equipment during the EPC Phases shall include the following but not limited to:

- Manage all mechanical and rotating equipment engineering activities within the project.

- Review and approve rotating equipment specifications, data sheets and requisition in accordance with the project requirements.

- Review and approve rotating equipment selection based on process design requirements

- Performing vendor data review and incorporation and assisting clients for the equipment installation and commissioning activities at site

- Performing technical bid evaluation in accordance with the Company requirements

- Responsible for enforcing the provisions and guidelines of the Quality Assurance

- Contribute to excellent HSE performance throughout the engineering phase of the project life cycle.

- Review and approve all EPC Contractor mechanical design.

- Prepare, check and approve all mechanical and rotating equipment engineering deliverables.

Mechanical Fix Equipment Engineering

ScientiCal Energy have a profound have knowledge in equipment calculation ,design and procurement of Fix equipment such as Pressure Vessels, Ex-changers, Storage Tanks, Packages etc. Preparation of requisitions for enquiry, Technical evaluation of bids and vendor selection, vendor's drawings and technical submittals checking, equipment acceptance and delivery.

Specialist knowledge:

- Fix Equipment Calculation, Design and Procurement Experience.

- Conversant with relevant design Software such as PVElite and TANK

- Conversant with relevant Oil & Gas Standards such as API, ASME and IPS

- Demonstrated experience with multi-disciplinary Terms.

- Technical capability and industrial certificates